SUMIKO planetary Gearboxes & Geared Motors are manufactured at Satara, Manchester of planetary Gearboxes starting from 40 Nm to 50000Nm in torque capacities with reduction ratios 3.5:1 to 10000:1 with single stage, double stage, triple stage, quadruple stage and five stages in normal conditions. We can also offer more ratios as per customers requirements

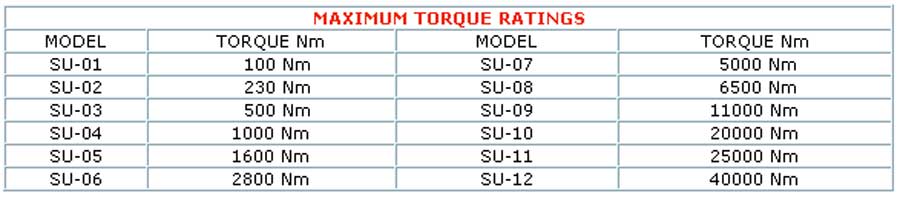

SUMIKO offers 12 different models starting SU-01 to SU-12. Out put mounting is Foot, Flange, Agitator with Solid Male Cylindrical shaft, Hollow Female cylindrical shaft with Keyway or Shrink Disc, Male Spline Shaft. Input mountings are Free (Solid Male Shaft) and Hollow shafts as per motor mounting frame size or motor mountings details for any type of prime movers.

SUMIKO Enterprises is a Proprietary firm launched in 2002. Since last two decades we expertise in Designing and Manufacturing any type of Planetary Gearboxes.

FEATURES

• Rigid In Construction

• Higher Efficiencies

• Compact In Size

• Versatile Mounting Arrangement

• Highest Reliability

• Suitable For Various Applications

• Flexible Input Types to Suitable Of Standard Motors

• Maintenance Free Operations

CONSTRUCTION

GEARS : Manufactured from high tensile alloy steels. Heat Treated for case carburizing, hardening and tempering. The Planets are carried on hard hushes or needle rollers mounted on high tensile case harden steel planet pins. The gears are lapped separately to improve the contact surfaces, durability, low noise level & high accuracy with special designed fixtures.

CARRIER : Manufactured from carbon steel or high strength graded cast steel. Carrier is engaged to output shaft or intermediate sun gears with involutes splines. Hard spacers are mounted with pins and planets to avoid friction.

SHAFTS : Manufactured from high tensile steel to resist bending and torsion strength.

BEARINGS : All rotating shafts are guided with antifriction bearings of standard make.

HOUSINGS : Input housings are Manufactured from graded cast iron. Outout housings are manufactured from garded cast iron below 1500 Nm torque and cast steel for above 1500 Nm torque capacities.

OILS SEALS : Nitrile rubber oil seal are used for standard applications. Special high temperature viton oil seals are used on request or as per applications.

SELECTION PROCEDURE : Followng parameters are considered for selcting the gear boxes to give the proper expected life and perfomance.

• Desired Output Speed

• Working Hours per day

• Start and Stops per Hour

• Orientation

• Input Horsepower and Speed

• Overhung Load

• Axial Load and Radial Load

• Enviornmental Conditions:

• Efficiency of Gearbox

RATIO : Ratio is the factor of division of input speed by outpur speed. We have to select closest available ratio from our selection table.

1. Selection of Service Factor (SF) Moderate shock & 15 hrs a day duty cycle. Consider service factor as per our table for selection of service factor is 1.5

2. Calculation of Ratio :

Input Speed

Ratio = —————–

Output Speed

1440

Ratio = —————–

47

Ratio = 30.63

3. Efficiency : It is observed that 30 ratio is achieved in tow stages Which has 90% efficiency

4. Calculation of Output Torque :

716.2 x HP x SF x Efficiency x 9.8

Output Torque = ——————————————

Output Speed

716.2 x 20 x 1.5 x 0.90 x 9.8

Output Torque = ——————————————

47

Output Torque = 4032 Nm

Please Select gearbox as per out selection table. If it is not suitable for thermal rating please take higher for suit Thermal rating as per higher torgue rating as per Thermal rating adjustment factor chart.

5. Mounting : Foot, Flange, Agitaor as per your application

6. Over hung load :

7. Orientation :

8. Axial & Radial Load :

9. Special Requirements : Special Material construction as per customer’s requirements can be offered

The Selected Model is SU-208 Ratio is 30.7